About Us

Shenzhen Xinfuhong Technology Co., Ltd.

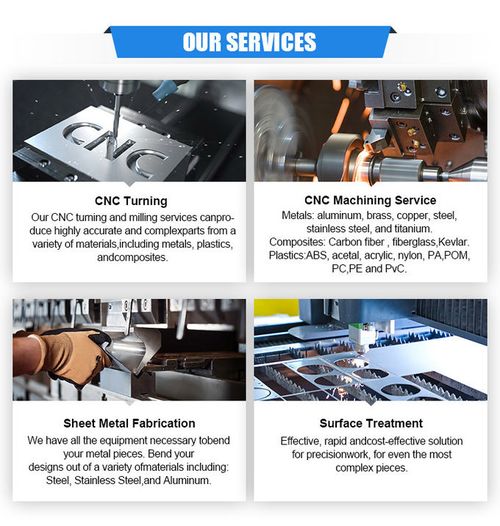

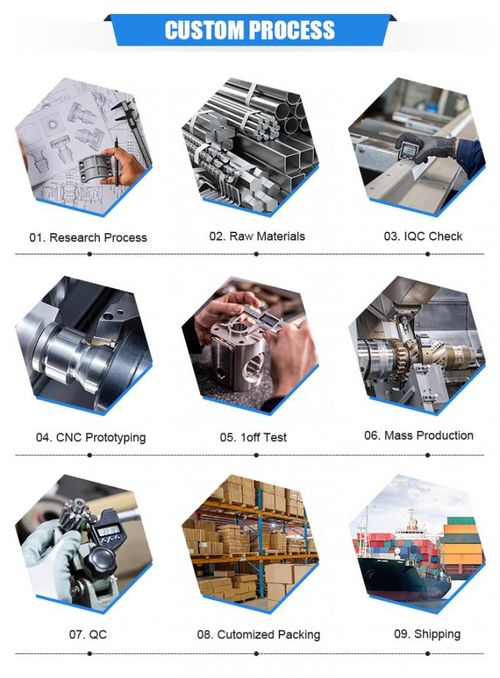

Your Professional and Trustable CNC Machining SupplierWe excel in CNC machining service, CNC turning service, CNC miling service, CNC drilling service, CNC grinding service wire/laser cutting service and surface / heat treatment for most metal materials.Instead of merely offering individual products, we provide comprehensive machining services and technical solutions to meet your ultimate needs.We pay close attention to and align with your processes, responding promptly to your demands, allowing ...